MVDirona.com |

||

|

|

|

|

Belts and Idler Pulley

Here's one that is worth checking every six months or so if you have a Cummins

B-series engine. It's easy, doesn't take very long and could save you a

lot of money. Cummins B-Series engines have seen what looks to be somewhat

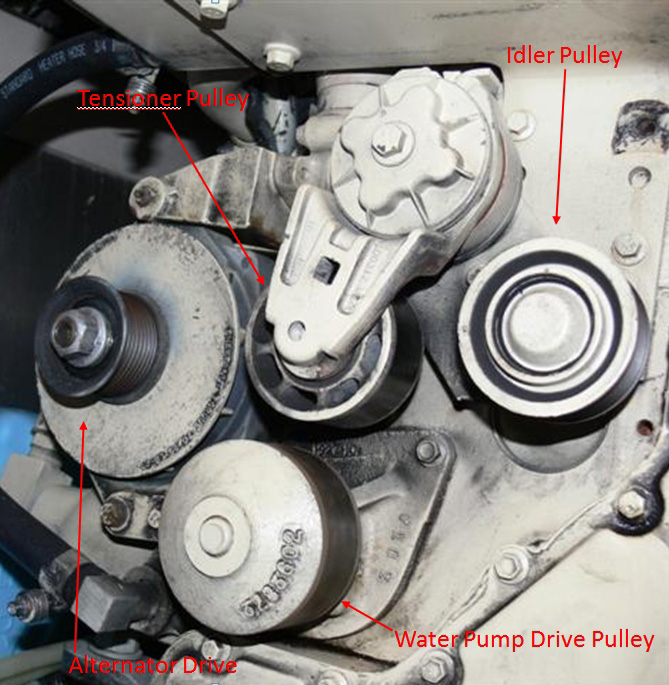

higher than nor This check is easy. First remove the drive belt safety cover. Note that the tensioner pulley mount has a 3/8" square opening in the face. You can see it in the picture or the right side of the page. It's the square opening just to the right of the arrow head that points to the tensioner pulley. Use a 3/8" breaker bar (or ratchet) to relieve belt tension and then remove the belt. First look at the belt. It's normal to see some minor cracks across the ribs in the belt and this is perfectly fine (see picture below).

If you see any longitudinal cracks or any cracks, cracks across more than one rib in line (see picture below), or deep cracks, then replace the belt. This belt should have been replaced some hours before.

Once you have finished checking the belt, you can check the idler pulley for wear. I check each pulley (see picture at top right of page) by spinning and listening for bearing noise. If you feel looseness or if the bearings aren't smooth to turn, replace the part. Apply this same check to the alternator bearings. If they are rough, send the alternator out for service. Also check the water pump for looseness or rough spots. If you look closely at the top picture, you'll see excess belt dust. I run the alternators at the high limit of their acceptable charging rate (see /TechnicalArticles/ChargingSystem.htm). While investigating just how hard these Delco alternators can reliably charge, I ran this one for a period hotter than it should be. Just a few hours at high temperature (charging excessively) will produce excess belt dust. If you see excess belt dust, investigate over-charging (alternator over around 220F), belt alignment, or binding bearings. In my case, I replaced the alternator stator, bearings, reduced the charging rate to keep the alternator under 220F, and put a new belt on and it's run for thousands of hours since. That's it. Reassemble and plan to check it again in 6 months or a year if you don't put many hours on annually. If you move quickly, you can do both in under 30 minutes. |

||

| Comments or questions? Feel free to contact us at Jennifer@mvdirona.com or jrh@mvdirona.com. |

Copyright 2012 Jennifer and James Hamilton |

|

mal

failures on the serpentine drive belt idler pulley so it's worth checking it

periodically. Since the drive belt runs the engine coolant pump, failure

can lead to engine overheat which is one of the fastest ways to end a diesel's

life early. I mentioned that the B-Series have had what looks anecdotally

like more idler pulley failures than would be expected but I would recommend

this check regardless of what type of engines you are running.

mal

failures on the serpentine drive belt idler pulley so it's worth checking it

periodically. Since the drive belt runs the engine coolant pump, failure

can lead to engine overheat which is one of the fastest ways to end a diesel's

life early. I mentioned that the B-Series have had what looks anecdotally

like more idler pulley failures than would be expected but I would recommend

this check regardless of what type of engines you are running.